STS

Lap Splicer

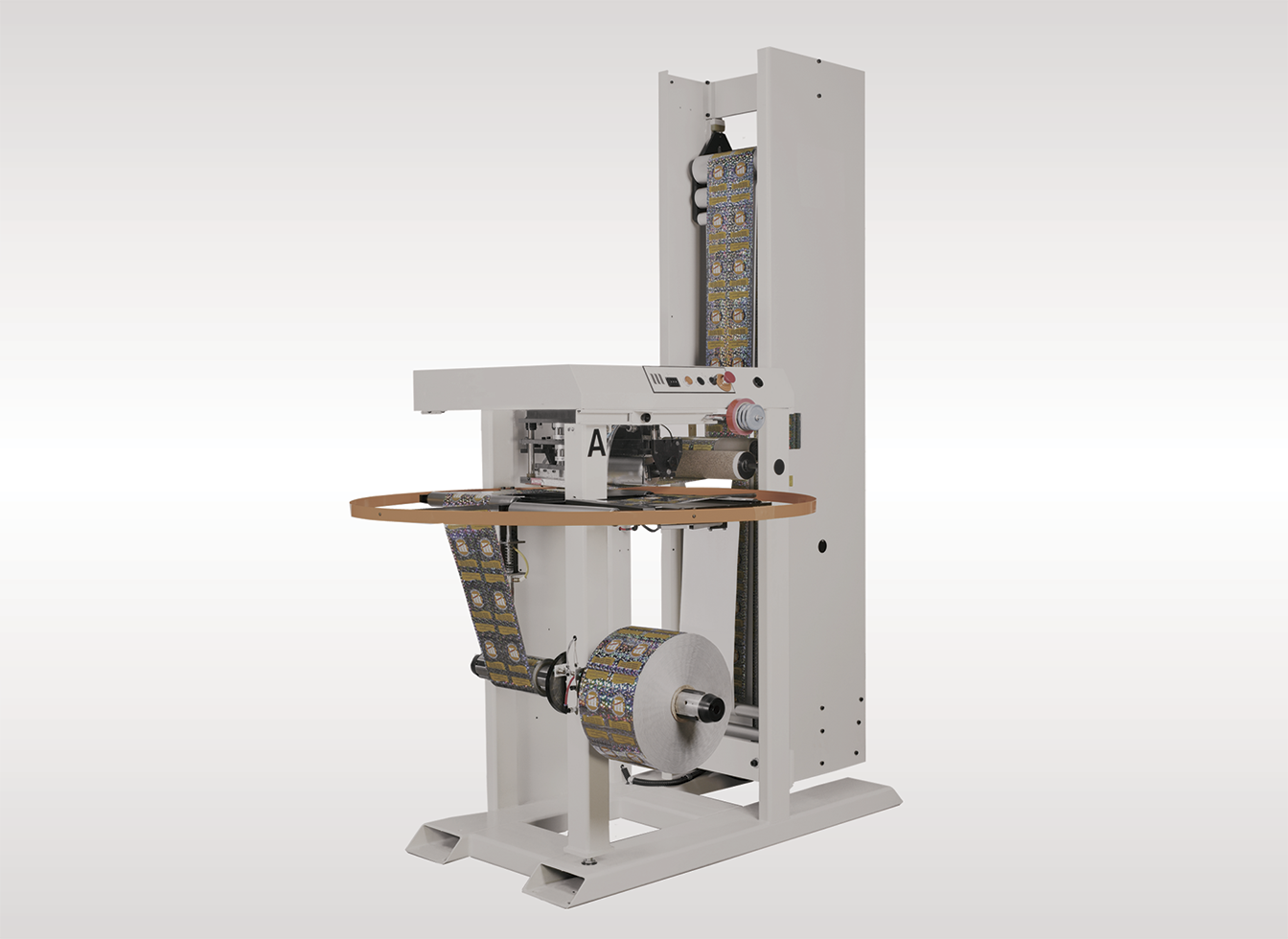

STS Automatic Lap Splicer

The Martin STS Automatic Splicer is ideal for nonstop production in pressure-sensitive label converting, packaging operations and other narrow web processes. The STS is a compact unit for continuous, full-speed unwinding of rolls. The unique turret design of the STS yields a space-saving footprint without compromising operator convenience.

The STS can be supplied to make the following types of splices:

- Taped overlap splices

- Taped butt splices, straight or angled, with single or two-sided tape

- Tapeless, heatseal overlap splices with no leading or trailing splice tails

The splice cycle begins at a pre-set roll diameter or on an operator signal. The running roll is stopped, while the storage festoon continues to feed web to the process. The splice unit cuts off the expired web, the turret rotates the new roll into position and the STS completes the splice-all without stopping or slowing the process.

Simple splice preparation and few operator controls are typical of Martin’s engineering philosophy. The standard DC drive package and PLC-based control system guarantee a high level of splicing reliability with minimal maintenance.

Specifications*

| Maximum Splicing Speed | 500 fpm | 152 mpm |

| Maximum Web Width | 13 in | 330 mm |

| Maximum Roll Diameter | 31.5 in | 800 mm |

| Electrical requirements | 110V/1PH/50-60 Hz | |

| Pneumatic requirements | 80 psi | 5 ATM |

*Specifications are meant as a general guideline. All Martin Automatic machinery can be application-engineered to fit specific process needs.

Standard Features

- Taped overlap splices

- Taped butt splices with single side tape application always on the bottom side of the web

Optional Features

- 15 Degree splice angle

- Pneumatically adjusted tension

- In-Register Splicing Package

- Taped butt splices with tape on both sides of the web

- Tapeless heat seal overlap splices with no leading or trailing splice tails