MBX

Butt Splicer

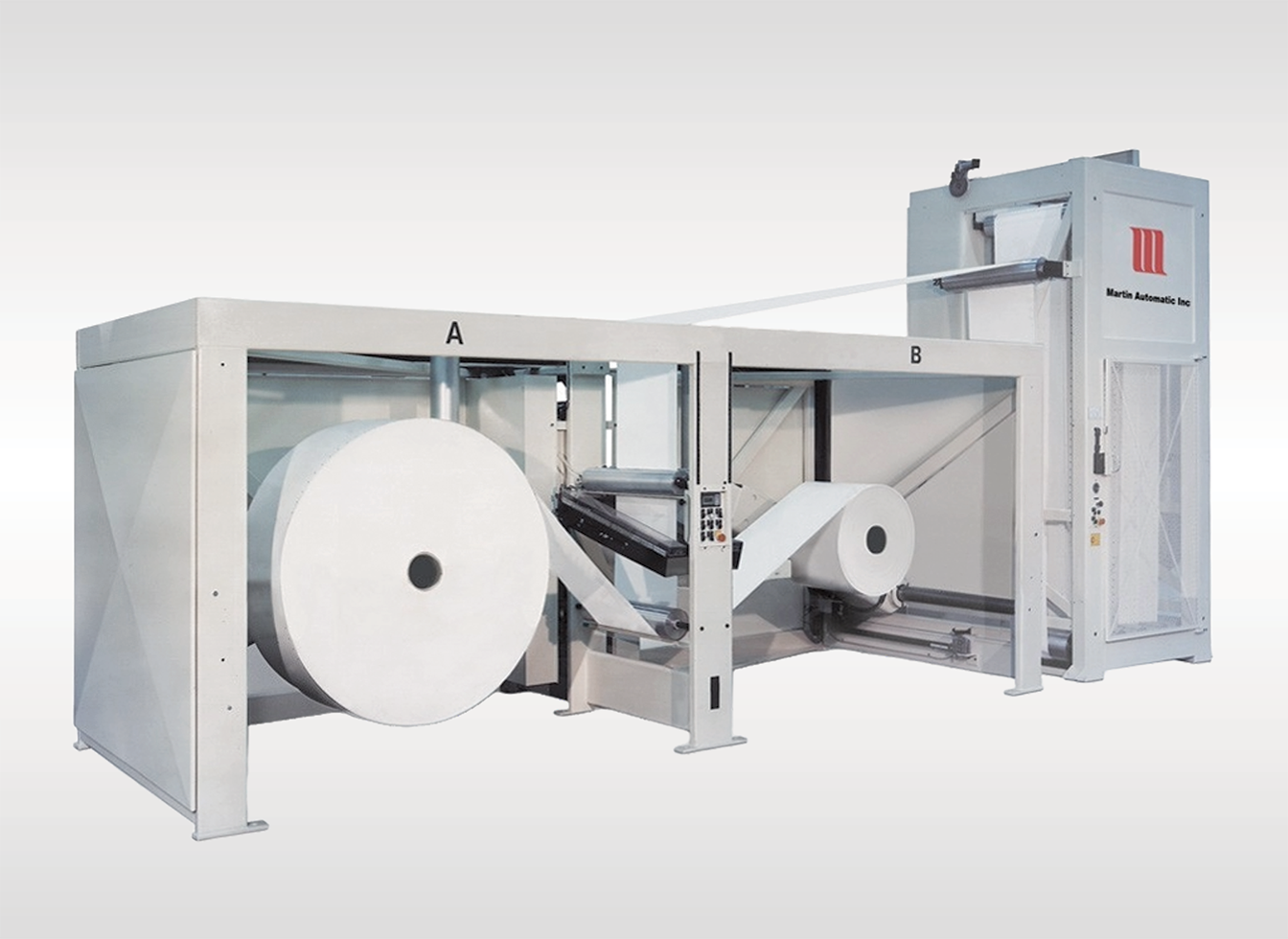

MBX Automatic Butt Splicer

The largest in the Martin MB Series of butt splicers, the MBX offers all the popular features of the MBS splicer but with added flexibility to converters seeking to run PS label stock, flexible packaging, pouch laminate, and paperboard with roll diameters up to 72 in (1800 mm) and out to 33 in (850 mm) web widths. As with all Martin products, the MBX Butt Splicer can be application-engineered to fit each process.

Design features of the MBX include:

- Reliable rolling shear splice unit. This patented butt splice unit simultaneously severs the web and irons tape across the splice, producing a tight bond. The precision shear wheel and anvil mechanism guarantees a clean cut and no overlap. A second rotary nip applies tape to the backside of the splice.

- Lift-and-load. A patented, built-in roll handling system lifts rolls up to 3100 LBS (1406 KG) from the aisle, without the need for auxiliary roll loading equipment.

- Automatic sidelay. This feature maintains the alignment of the running web to the prepared web in the splice unit. A sensor monitors the position of the running web, and the automatic sidelay system compensates to insure that the webs are aligned at the time of a splice.

- Inertia compensated tension control. The festoon features Martin’s inertia compensation technology for consistent, accurate tensioning of the web as it enters the process.

- Automatic splice initiation. The MBX monitors the diameter of the running roll and automatically makes a roll change at a pre-set diameter. Alternatively, the tail grabbing function initiates a splice as material separates from the core for maximum material usage and minimum waste.

- Soft tension features. The MBX can be equipped to handle a wide range of materials, including delicate film webs. Driven unwind packages are available for lightweight stocks requiring very low tension levels and strictest tension accuracy.

Specifications*

| Maximum Splicing Speed | 1300 fpm | 396 mpm |

| Maximum Web Width | 33 in | 838 mm |

| Maximum Roll Diameter | 72 in | 1829 mm |

*Specifications are meant as a general guideline. All Martin Automatic machinery can be application-engineered to fit specific process needs.

Standard Features

- Adjustable running web tension

- Integrated pneumatic loading

- Bi-directional unwind capability

- Automatic roll sidelay

- Automatic splice initiation

- Angled butt splice, taped both sides

- Precision tape dispensers

- Inertia Compensated Festoon

- Patented lift-and-load system with pneumatic spindles

Optional Features

- Festoon and Accelerator packages to match process speeds

- Soft tension control package for film webs

- Explosion-proof provisions

- Splice unit and spindle diagnostic package

- Custom rollers for specific material requirements

- Transparent web sensing provisions

- Dual unwind capability with two-web tension control