MBSC

Butt Splicer

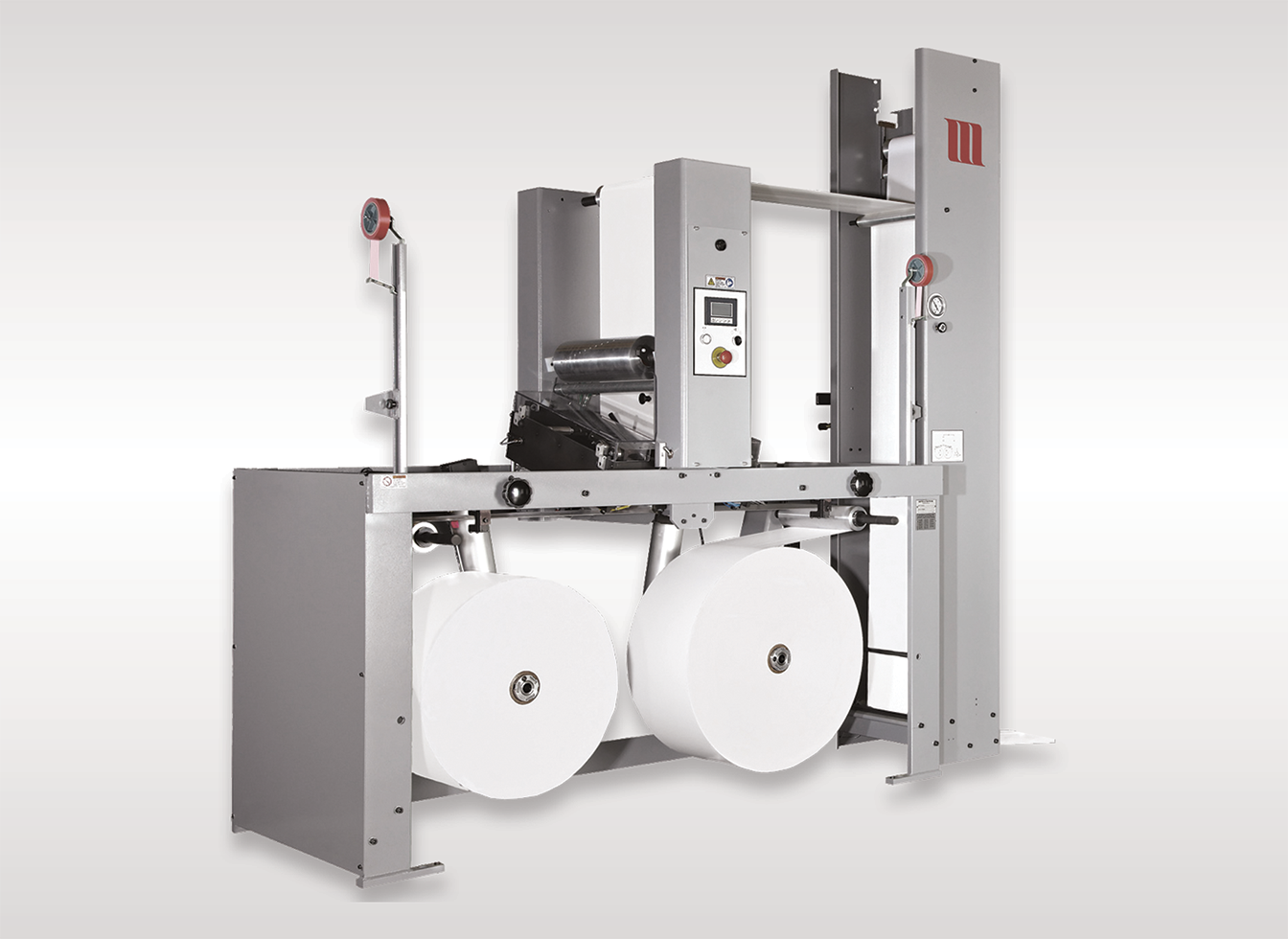

MBSC Automatic Butt Splicer

Compact, full-featured butt splicer for non-stop unwinding on 13 in (330 mm) width label presses. The benefits of automatic splicing add up to significantly increased productivity, greater quality control and reduced waste. The MBSC applies these benefits to label converting and narrow web applications. The MBSC is a compact butt splicer that shares the same simplicity, reliability and many of the features of our larger splicers. As with all Martin products, the MBSC Butt Splicer can be application-engineered to fit each process.

Design features of the MBSC include:

- Reliable rolling shear splice unit. This patented butt splice unit simultaneously severs the web and irons tape across the splice, producing a tight bond. The precision shear wheel and anvil mechanism guarantees a clean cut and no overlap. A second rotary nip applies tape to the backside of the splice.

- Lift-and-load. A patented, built-in roll handling system lifts rolls up to 400 LBS (200 KGS) from the aisle, without the need for auxiliary roll loading equipment.

- Automatic sidelay. This feature maintains the alignment of the running web to the prepared web in the splice unit. A sensor monitors the position of the running web, and the automatic sidelay system compensates to insure that the webs are aligned at the time of a splice.

- Inertia compensated tension control. The festoon features Martin’s inertia compensation technology for consistent, accurate tensioning of the web as it enters the process.

- Automatic splice initiation. The MBSC monitors the diameter of the running roll and automatically makes a roll change at a pre-set diameter. Alternatively, the tail grabbing function initiates a splice as material separates from the core for maximum material usage and minimum waste.

Specifications*

| Maximum Splicing Speed | 600 fpm | 200 mpm |

| Maximum Web Width | 13 in | 330 mm |

| Maximum Roll Diameter | 31.5 in | 800 mm |

*Specifications are meant as a general guideline. All Martin Automatic machinery can be application-engineered to fit specific process needs.

Standard Features

- Patented lift-and-load roll loading

- Capacity for two full-diameter rolls at any time

- Reliable, patented rolling shear splice unit for clean cut-off and tight splices

- Angled butt splice taped both sides

- Bi-directional unwind capability

- Automatic roll sidelay for use with opaque and transparent webs

- Martin inertia-compensated tension control system

Optional Features

- Portability package

- Full Dual Unwind ( 2-web unwinding for occasional lamination work)