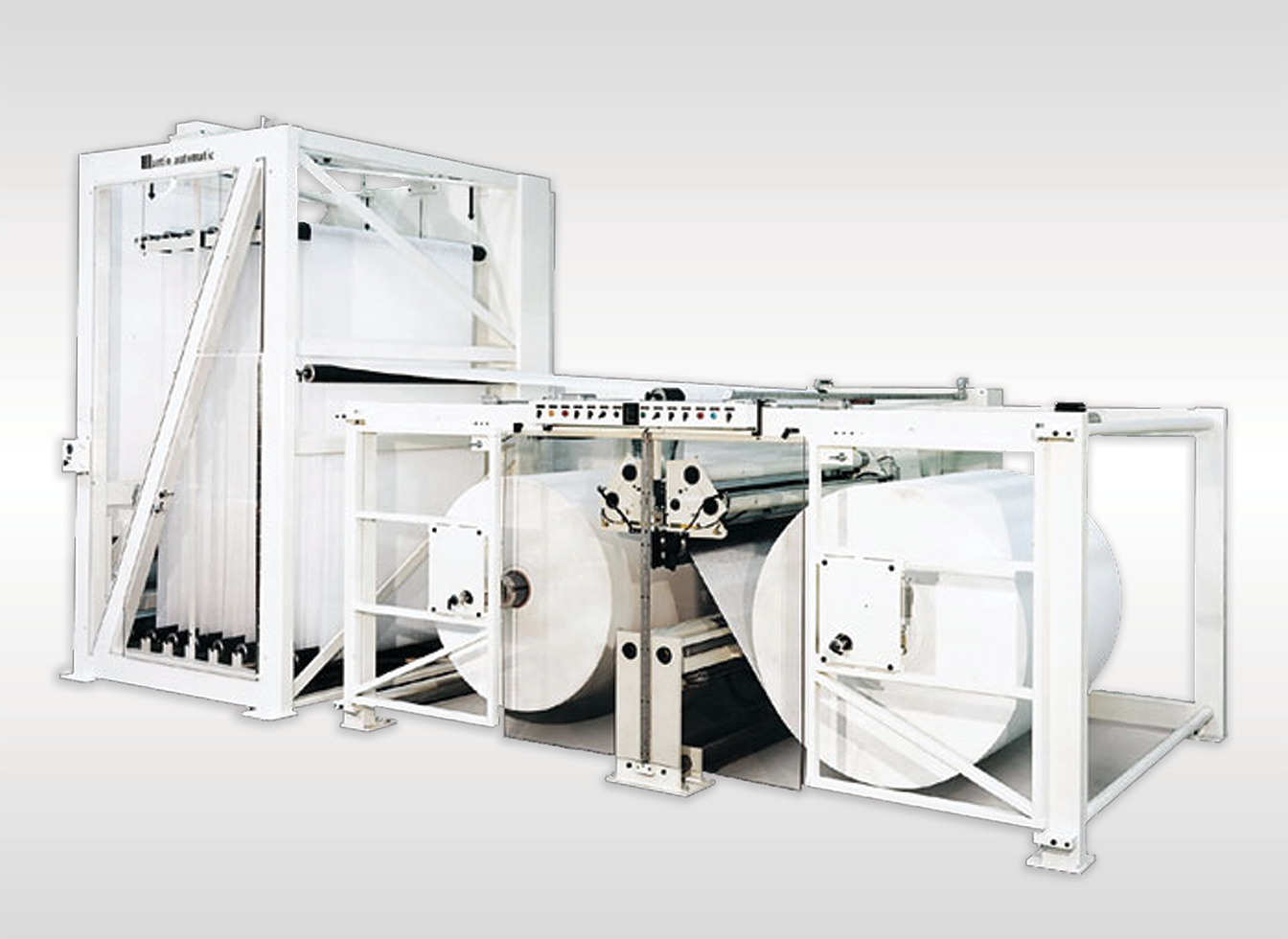

CHW-WW

Heatseal Splicer

CHW Wide Web Heatseal Splicer

A creative and effective answer to automatic splicing of non-wovens, tissues and extensible films.

- The CHW (cantilevered hot-wire splicer) is Martin’s creative and effective answer to automatic splicing of non-wovens, tissues and extensible films. An integrated roll spindle/splice unit, hot-wire cut-off system and patented tension control system combine to offer the manufacturer using non-woven, tissues or extensible films incomparable value in automatic splicing and tension control.

- The integrated roll-spindle/splice unit allows in-aisle roll loading and splice preparation. The splice unit has been designed as two separate halves, with one half of the splice unit attached to each roll-spindle structure. The roll-spindle/splice unit extends into the aisle allowing unobstructed roll leading splice preparation. A pneumatic lift carries the roll back into its running position.

- A hot-wire cut-off system replaces the traditional knife cut-off system found on most splicers. This hot-wire system is a safe, clean and reliable alternative to knife systems. In addition, the CHW hot-wire system automatically trims the leading edge of a newly prepped web, ensuring a consistent tail-length.

- The CHW is designed to run at tensions as low as .5 lb total tension. A patented tension control system incorporated with either spindle drives or Martin’s unique braking system ensures tension accuracy within .25 lb total variation during running and splicing cycles.

Specifications*

| Maximum Splicing Speed | 2500 fpm | 762 mpm |

| Maximum Web Width | 75 in | 1905 mm |

| Maximum Roll Diameter | 60 in | 1524 mm |

| Electrical requirements | Per application | |

| Pneumatic requirements | 80 psi | 5 ATM |

*Specifications are meant as a general guideline. All Martin Automatic machinery can be application-engineered to fit specific process needs.

Standard Features

- Fixed, cantilevered spindle design

- Lift-and-load feature keeps rolls close to the ground

- Pivoting split splice unit

- Easy access, in-aisle splice preparation

- Hot wire cut-off for either lap or optional heat-seal butt splice

- Tape lap splice

- Out-board support for securing rolls in the running position

Optional Features

- Heat seal lap splice

- Martin’s patented Heat Seal Butt Splice

- CE Certification

- 3/4” Expansion spindles for easier roll loading

- In-Register Splicing Package