CHW

Lap Splicer

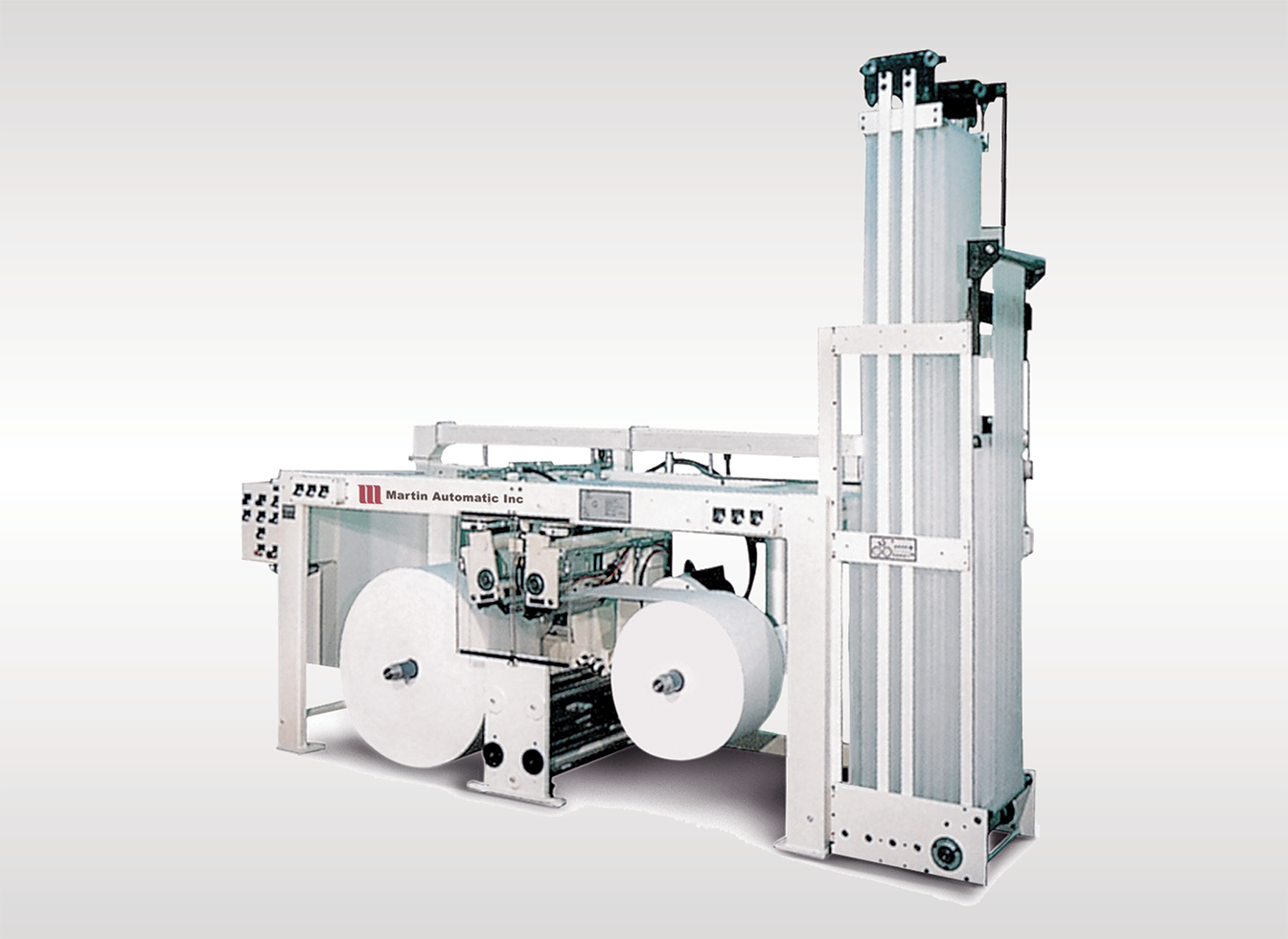

CHW Automatic Lap Splicer

Automatic roll changing for nonwovens, tissues and extensible films.

- The Martin model CHW cantilevered, hot wire lap splicer reliably joins nonwovens and extensible films at low tension. The side by side roll configuration of the CHW features integrated roll spindle and splice units, hot-wire cut-offs and patented tension control.

- Each integrated roll-spindle and splice unit allows in-aisle roll loading and splice preparation. One half of the splice unit is attached to each roll-spindle assembly. Each roll-spindle and splice unit moves into the aisle to load the roll and provide unobstructed splice preparation. Pneumatic cylinders lift the rolls prior to splice preparation.

- The hot-wire cut-off system replaces the traditional mechanical knife cut-off system found on most splicers. The hot-wire is a safe, clean and effective method of cutting non-wovens and films. In addition to cutting the expiring web, the CHW’s hot-wire system automatically trims the leading edge of the new web, ensuring a consistent tail-length of one to two inches.

- The CHW is designed to run at as low as 0.5 lbs of total tension. Martin’s patented inertia compensated tension control system works in conjunction with spindle drives or Martin’s proprietary braking system to provide a tension accuracy within 0.25 lbs of set tension during both running and splicing cycles.

- Martin models CHW-WW, NCHW and THW are variations of the CHW. Other related options include the mechanical knife for running tissue stock and the Heat Seal designs for butt and lap heat seal splicing of non-wovens and films.

Specifications*

| Maximum Splicing Speed | 1500 fpm | 457 mpm |

| Maximum Web Width | 20 in | 508 mm |

| Maximum Roll Diameter | 60 in | 1524 mm |

*Specifications are meant as a general guideline. All Martin Automatic machinery can be application-engineered to fit specific process needs.