Latest News

Martin Automatic to Exhibit at Labelexpo Europe 2025 in Barcelona

Building on the successful collaboration at Labelexpo America 2024, Martin Automatic, ETI Converting, LEMU Group and Lundberg Tech will be collaborating again at Labelexpo Europe. The four companies will be showcasing a live production job for Mirmar SA, a Spanish label converter.

Martin Automatic celebrates a world-first at Labelexpo – and makes plans for the future

Gavin Rittmeyer, VP Sales & Marketing at the Rockford based manufacturer, reflects on a successful three days in Chicago that saw a unique experiment in integration come to fruition.

Martin Automatic in 60 seconds

Step into the world of Martin Automatic in this 60-second interview with Jordan Martin, owner of Martin Automatic, and Gavin Rittmeyer, VP of Sales & Marketing.

Latest News

Martin Automatic to Exhibit at Labelexpo Europe 2025 in Barcelona

Building on the successful collaboration at Labelexpo America 2024, Martin Automatic, ETI Converting, LEMU Group and Lundberg Tech will be collaborating again at Labelexpo Europe. The four companies will be showcasing a live production job for Mirmar SA, a Spanish label converter.

Martin Automatic celebrates a world-first at Labelexpo – and makes plans for the future

Gavin Rittmeyer, VP Sales & Marketing at the Rockford based manufacturer, reflects on a successful three days in Chicago that saw a unique experiment in integration come to fruition.

Martin Automatic in 60 seconds

Step into the world of Martin Automatic in this 60-second interview with Jordan Martin, owner of Martin Automatic, and Gavin Rittmeyer, VP of Sales & Marketing.

Installations

Countries

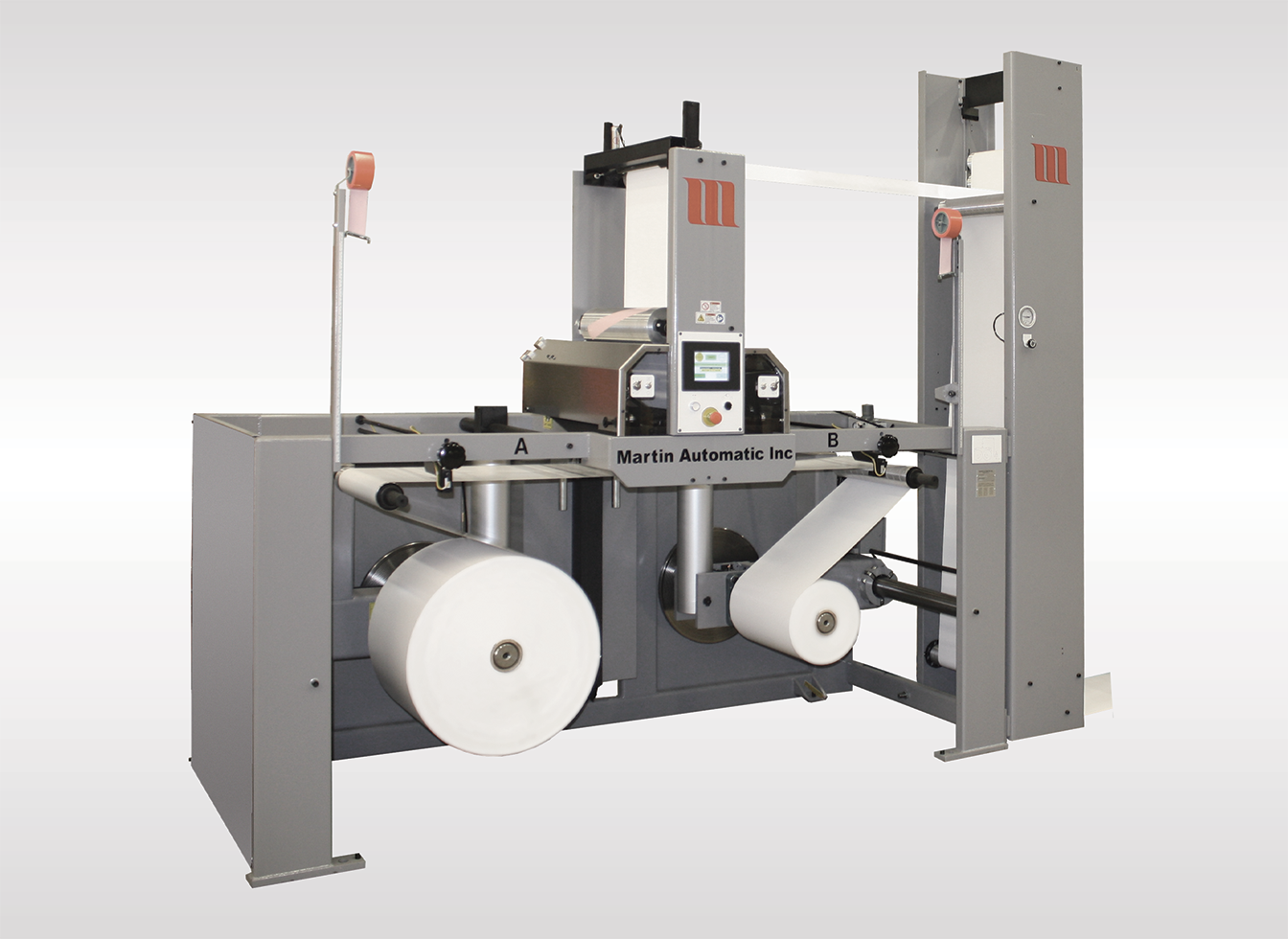

Featured Products

Recent Testimonials

"As well as improving productivity and showing a fast ROI, the Martins have had a motivational effect on the production teams, who now deliver a higher volume of saleable product with less physical effort."

– Mischa Barthel, Managing Director, Barthel Group

"One look at the production line here and it's obvious how much difference automating the roll changes can bring. Rolls of 60" diameter 400-micron paper are heavy and slow to manipulate, and with typically two changes per hour that took 10 minutes each when done manually - it's easy to assess the improvement in productivity that our MBX unit has made."

– Achim Peters, Managing Director, Peters GmbH

"With their compact dimensions and full features, our MBSC and STR are specially designed for smaller production environments, but they still offer fully automated roll handling for continuous running. This is another example of Martin's tailor-made engineering."

– Dušan Prevrátil, Production Director, Colognia Press

"We save around 5-10% of material and 5-10 minutes per roll change with our Martin equipment – this makes a significant contributions to productivity and therefore profitability, and it also has a beneficial effect on the environment."

– Edmund Chan, Group General Manager, Mega Label

"By allowing us to run our presses non-stop at optimum speed, Martin Automatic technology has been a major factor in us achieving our cost and productivity goals, which would have been impossible otherwise. Each one of their systems here, now numbering 21 with another to come shortly, is a model of reliability."

– Chris Allen, Maintenance and Quality Manager, OMNI Systems

Read more

Click here to see more customer testimonials and read our latest press releases, news articles, opinion pieces, and more.

Download our full product brochure

Learn more about our web handling expertise in automatic unwinds, rewinds and tension control systems.